How Matterport and Maximo Are Harnessing Property Data Across The Property Lifecycle

At the 2025 Northeast Maximo User Group (NEMUG) conference, Matterport showcased how digital twins are reshaping facilities management using data from digital twins across the property lifecycle—making buildings smarter, maintenance more proactive, and connecting teams cross-functionally.

Digital twin technology has emerged as a cornerstone of Industry 4.0, especially for facilities and asset-intensive operations. In her NEMUG presentation, Stephanie Lin, VP and GM of Operate Solutions at Matterport, laid out how combining spatial data with real-time insights from Maximo can unlock efficiency across the property lifecycle.

What is a digital twin in facility management?

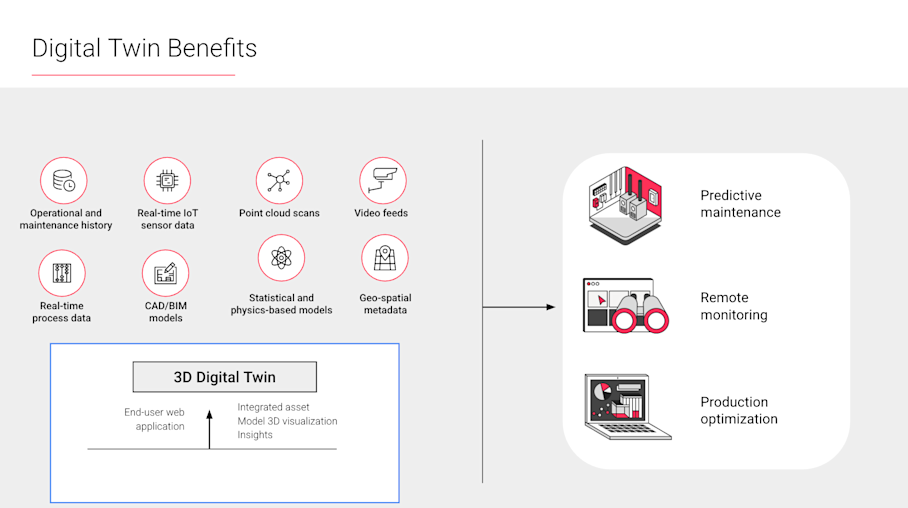

A digital twin is a real-time, 3D digital replica of a physical space, dynamically updated with data from sensors, assets, and operational systems. It enables facilities teams to:

Remotely monitor and inspect assets

Simulate conditions and predict failures

Collaborate across departments in one unified interface

JFC & Associates’s innovative CONNEX solution showcases the practical value of integrating IoT sensor data with enterprise asset management platforms like IBM Maximo, while connecting meter data in the digital twin, where the spatial context provides a single source of truth for operations and can be easily accessed for virtual visual walk-downs, surveys, or everyday management needs.

How digital twins are making an impact in Industry 4.0

Digital twins are no longer emerging technology—they're a strategic priority for organizations looking to future proof facility operations:

$66B estimated global digital twin market size

63% of manufacturers are developing a digital twin strategy

92% report improved sustainability with digital twin adoption

With labor shortages, aging infrastructure, and increasing operational complexity, facility leaders are turning to digital twins to do more with less by making facility maintenance information accessible and accurate.

Key benefits of digital twins for facilities

Digital twins optimize the building management process across the following areas:

Reduce operational costs and downtime Digital twins help teams identify anomalies before they escalate, combining IoT, maintenance records, and live spatial data to improve asset uptime and performance.

Supports remote onboarding and training Digital twins enable manufacturing teams to create immersive, 3D replicas of facilities so new hires can be onboarded and trained remotely with photorealistic, interactive walkthroughs that reduce downtime and travel costs.

Enables better collaboration across different functions Maintenance teams and remote experts can virtually walk a site, access real-time data, and coordinate repairs—without needing to be physically present.

Accelerate maintenance with remote inspections Visual overlays of Maximo work orders within a digital twin allow field techs to locate, understand, and address issues faster.

Enhance sustainability and compliance Digital twins make it easier to track energy usage, optimize systems, and meet compliance requirements with full visual documentation.

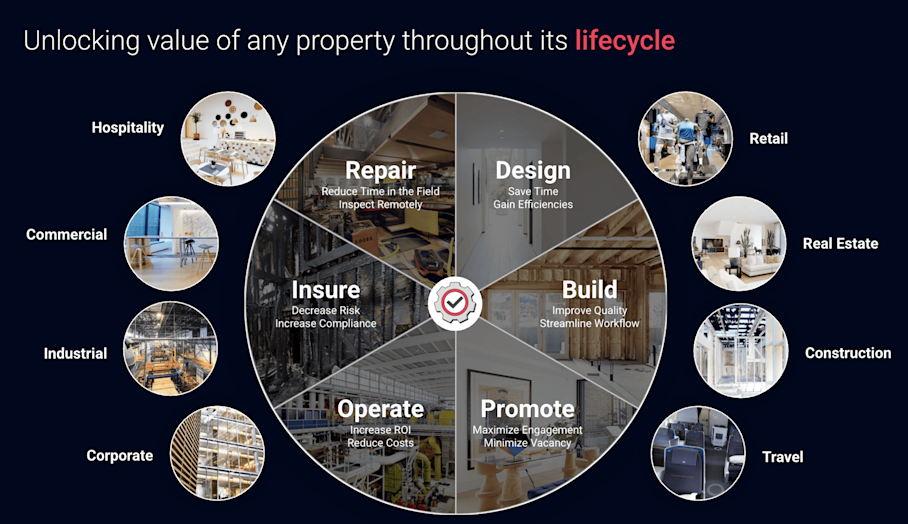

Digital twin applications across a facility building’s lifecycle

Matterport’s approach covers the entire building lifecycle, supporting everything from the initial preconstruction stage, during construction, and through to close out and long-term maintenance across different industry applications.

Phase | Use Cases |

Plan & Design | Site capture, BIM modeling, layout visualization, cost estimation |

Build | Construction progress monitoring, QA/QC, issue tracking |

Operate & Maintain | Asset management, training, remote diagnostics, Maximo integration |

Insure & Repair | Claim documentation, material replacement validation |

This full-lifecycle approach helps stakeholders across different phases reduce rework, streamline workflows, and extend the value of each property by staying on schedule and on budget.

Building lifecycle stakeholders | Benefits |

Architecture | Save time and reduce costs. Easily capture as-built conditions and kickstart your design process with high-fidelity, 3D data. |

Engineering | Reduce site visits and remove the guesswork. Make decisions faster and streamline your workflow without repeated and costly visits to the jobsite. |

Construction | Improve communication and reduce risk. Document project milestones and collaborate on issue resolution and progress monitoring. |

Facility maintenance | Stay operational 24/7. Manage your assets and maintain operational efficiency throughout every planned or unplanned event. |

Facility management | Stay ahead of facility workflows. Connect and train your people, document your assets, and fast-track your decision making processes. |

How IBM Maximo integrations improve facility operations

During the presentation, Matterport showed how users can navigate a virtual property and view Maximo asset data directly in the digital twin interface. This allows:

Real-time sensor readings (e.g., temperature, humidity)

Contextual alerts and asset histories

Faster onboarding for new technicians via AR/VR training

Proactive maintenance driven by condition-based triggers

This integration eliminates the data silos that often slow down decision-making in large organizations.

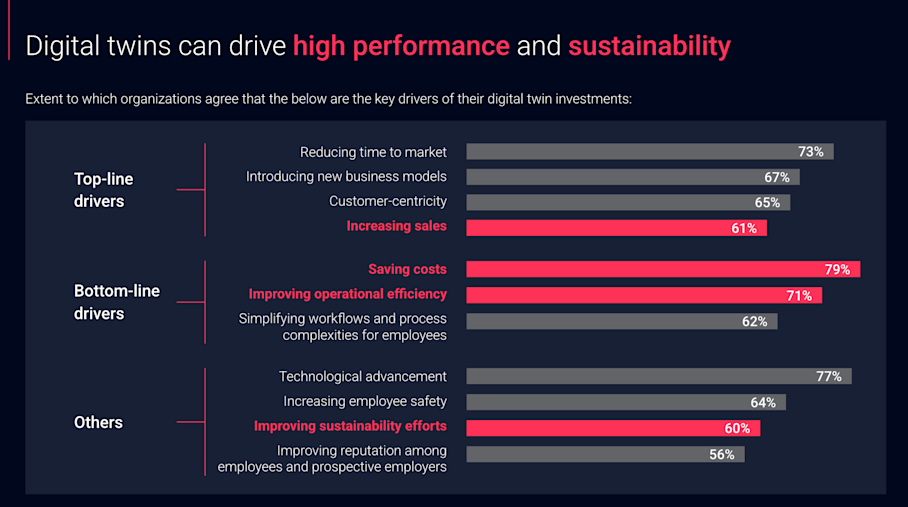

This also delivers real-world value in the long term that affect both the top-line and bottom-line:

Final Thoughts

As more facilities leaders invest in smarter, more connected infrastructure, the value of digital twin integrations with Enterprise Asset Management (EAM) platforms like IBM Maximo will continue to drive value for facility operations. These integrations give leaders a single, interactive view of their assets—linking spatial data with maintenance schedules, work orders, and performance metrics to improve decision-making and response times.

Matterport’s technology offers a scalable path to high-performance facility management. Ready to modernize your maintenance strategy? Digital twins might be your smartest next move.