Capturing Complexity, Delivering Confidence

Stantec’s Use of Matterport

Introduction

Stantec is a global design and engineering firm with over 32,000 employees across six continents, delivering professional services in planning, engineering, architecture, and environmental sciences. With deep expertise across buildings, infrastructure, water, energy and resources, and environmental services, Stantec brings a holistic, integrated approach.

At the strategic level, John Patten, Stantec’s Principal and client director for Penn Medicine, has been a driving force behind adopting Matterport across major healthcare projects. His leadership helped elevate Matterport as a core part of Stantec’s delivery model, positioning it as both a competitive advantage and a tool for improving client outcomes. On the project execution side, Zac Bradley, Project Designer at Stantec, has championed the platform’s integration into the firm’s day-to-day workflows. He led hands-on implementation across multiple sites, embedding Matterport into surveying, design coordination, and construction collaboration processes. Together, John and Zac have aligned leadership goals with practical site execution to standardize how spatial data is captured, validated, and shared across projects.

Challenge

Stantec frequently leads complex renovation projects in active healthcare environments, where speed, accuracy, and coordination are critical. These projects span aging infrastructure, expansions of modern medical facilities, and site adaptations driven by evolving healthcare delivery needs. Across this spectrum, a consistent challenge is the lack of reliable as-built documentation, which is often outdated or missing altogether. In environments like operating rooms, diagnostic suites, and mechanical spaces, even small measurement inaccuracies can derail schedules or require costly rework.

According to global management company McKinsey, large construction projects typically take 20 percent longer to finish than scheduled and are up to 80 percent over budget. In healthcare settings, these risks are amplified by strict regulations, limited access windows, and high expectations from both patients and facility stakeholders.

Stantec’s work with Penn Medicine highlights these challenges. Many of the buildings involved had undergone multiple renovations over the decades, with inconsistent documentation and irregular conditions that were difficult to verify in the field. Before Matterport, Stantec relied on traditional survey methods that required teams of three or four people to spend days measuring, sketching, and digitizing existing conditions, often returning multiple times to capture missed details.

During a recent 20,000-square-foot renovation of a medical office building, Stantec faced limited access to the space and incomplete building documentation. The project was designed to accommodate Hematology and Oncology Clinic services, Infusion spaces, and Pharmacy programs. Based on the available information, it was initially believed that a new rooftop air handling unit (AHU) would be required to meet program demands, which would have significantly affected both the project schedule and budget.

By using Matterport as an investigative tool, the team was able to verify that the existing AHU already served the project area. Using measurable scan data and the 3D environment viewer, Stantec collaborated with engineers and contractors to trace the existing ductwork from the rooftop, down through the shafts, and into the ceilings below. This discovery preserved the construction budget and prevented unnecessary changes to the existing infrastructure.

Solution

Stantec integrated Matterport across a growing portfolio of healthcare projects, particularly within its work for Penn Medicine. The technology is now embedded in workflows that span early site validation, construction documentation, punch lists, and even proposal development.

Streamlining Site Documentation and Surveys

One of the earliest use cases involved capturing existing conditions for fast-moving outpatient renovations. Matterport scans revealed critical discrepancies between legacy CAD files and actual field conditions, including unexpected wall chases, misaligned structural elements, and undocumented utilities. Rather than relying solely on outdated drawings, Stantec now imports point clouds from Matterport’s MatterPak into Autodesk Revit via Recap, ensuring model alignment to real-world geometry from the outset.

In traditional workflows, surveying an occupied space could take a team of three or four people multiple days. With Matterport, two team members can complete a comprehensive scan in a single afternoon, significantly reducing the labor hours and logistical challenges of site access, especially in high-traffic healthcare environments. Stantec can utilize their freed-up team members for other critical tasks.

Enhancing Design Coordination and Client Communication

Stantec also used Matterport to support major infrastructure planning, such as a $200 million renovation project for Penn Medicine. In this case, the team scanned key phases of the project, from demolition to above-ceiling inspections to final punch lists. These scans became a shared reference during construction meetings, used to resolve conflicts, validate conditions, and accelerate decision-making across teams.

In a recent 7,500-square-foot renovation of a hybrid operating room suite within an existing hospital, the project team identified a coordination conflict between existing ductwork and new overhead structural steel needed to support surgical equipment booms. The steel had to meet specific load requirements, but its placement interfered with the mechanical systems above the ceiling. Fortunately, the team had scanned the space during the demolition phase using Matterport. This documentation allowed them to revisit actual field conditions virtually and work directly with construction managers and engineers to evaluate solutions. By referencing the 3D scans alongside the contractor’s steel shop drawings, the team identified a cost-effective path to reroute the ductwork and pinpoint accurate locations to anchor the structural steel to the deck above. This approach avoided invasive rework, prevented schedule delays, and ensured the surgical equipment could be supported safely within the tight above-ceiling space.

When an engineering detail was questioned by a contractor, the Matterport model was used to visually confirm the equipment in question. This immediately ended the dispute, improving confidence in field documentation and saving time that would have been spent in back-and-forth coordination.

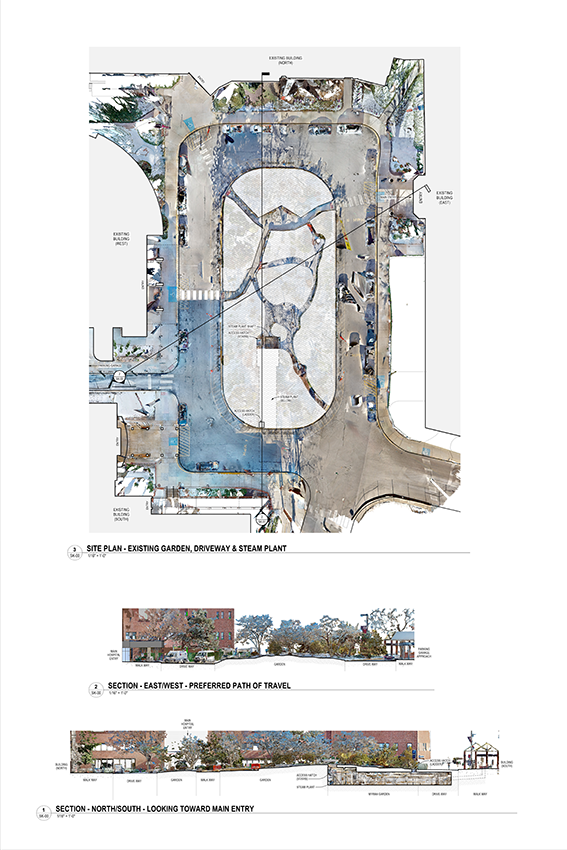

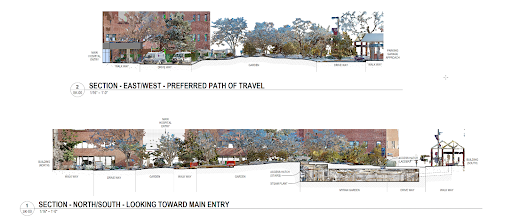

Matterport also played a central role in a site feasibility study involving a buried steam plant and courtyard. Using 126 scans, Stantec documented the below-grade infrastructure and surface conditions to assess visibility challenges caused by a new parking garage. The team overlaid the point cloud onto existing site plans to calculate grades, section views, and view corridors, enabling a data-informed recommendation to improve wayfinding for patients and visitors.

This feasibility study helped Penn Medicine explore how to restore visibility from a parking garage to the main hospital entry. The Matterport scan enabled analysis of grade, massing, and section views.

Supporting Proposals and Visualization

Matterport has also proven valuable in early-stage pursuits. In one example, Stantec used the platform to scan an entire city block in Chicago, delivering e57 files and site imagery to their graphics team for integration into proposal renderings. This helped differentiate Stantec’s submission with more accurate visuals and utility mapping, ultimately making the bid more competitive.

Exploring Asset Tracking and Facilities Integration

Looking ahead, Stantec is working with Penn Medicine to explore how Matterport can support facilities teams’ post-construction. They are evaluating the use of Matterport tags to link specific equipment and infrastructure to asset databases or Revit schedules. While still in early stages, the vision is to provide facilities personnel with interactive, visual records of their spaces, bridging the gap between design, construction, and long-term building operations.

In collaboration with building facilities teams, Stantec expanded its use of Matterport to support a more integrated BIM workflow for asset management. The team models, tags, and links data gathered during the submittal review process directly to maintainable assets within the building environment. This approach results in a comprehensive set of digital records that are fully aligned with the final BIM model and record drawings. While the specific systems vary by project, typical asset candidates include variable air volume (VAV) boxes, grilles and diffusers (GRDs), electrical panels, light fixtures, plumbing fixtures, medical gas outlets, sprinkler heads, doors, and other building components that facilities teams manage throughout the operational lifecycle. By combining Matterport’s spatial visualization tools with metadata from design and construction, owners bridge the gap between project turnover and long-term facility operations.

Results

By implementing Matterport across its Penn Medicine projects, Stantec has achieved:

60 to 70 percent reduction in time spent documenting existing conditions

Improved model accuracy, by aligning Revit to real-world scans

Enhanced collaboration, enabling faster decisions in meetings

Stronger client engagement, using immersive models to improve visibility and buy-in

Matterport has significantly reduced the number of RFIs that stem from field documentation issues. Team members now reference the 3D model to verify dimensions and clarify scope, which decreases rework and improves contractor accountability.

The platform has also helped shift internal mindsets. As Bradley shared, “Static photos just don’t cut it anymore.” This growing reliance on spatial data has made Matterport a core component of how Stantec delivers complex healthcare renovations—providing a consistent visual record across the life of each project.